Pressure swing adsorption air separation equipment

Pressure swing adsorption oxygen production equipment

▉ Producing product gas by the principle of absorption, the process of which is shorter and energy consumption is lower than the cryogenic process.

▉ The construction period is short, the area required is small, and the process can be easily restarted and stopped.

▉ Suitable for working conditions with oxygen purity between 75-93% and oxygen consumption below 5000Nm3/h.

Application field

Non-ferrous metal smelting, oxygen-rich blast furnace iron smelting, arc furnace steelmaking, ozone denitrification, pulp bleaching, sewage treatment, etc

Working principle

Technical index

Nitrogen output: 1~3000Nm3/h

Nitrogen dew point : -40~-70℃

VPSA oxygen production equipment

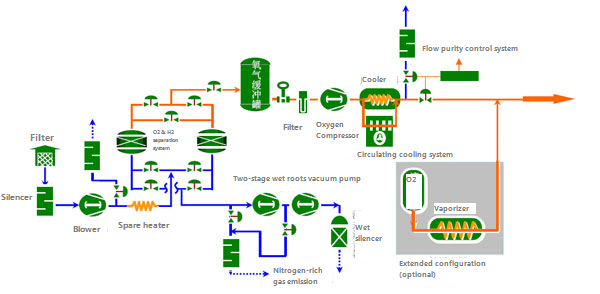

Working principle:

The vacuum pressure swing adsorption oxygen production equipment uses high-quality oxygen production molecular sieve to adsorb nitrogen, and the unadsorbed oxygen gathers at the top of the tower and is transported to the oxygen storage tank as product gas. When the adsorption tower in the adsorption state is close to saturation, the tower will automatically decompress and desorb and regenerate, and the other adsorption tower will begin pressurized adsorption to produce oxygen. The two adsorption towers work alternately to complete the oxygen production process.

Technical features:

(1)The amount of civil works is small, the installation period of the device is shorter than that of the cryogenic device, and the investment is low ;

(2) Low energy consumption for oxygen production, and low equipment operation and maintenance costs;

(3)The device has a high degree of automation, it is convenient and quick to start and stop, and requires fewer operators ;

(4)The device has strong operation stability and high safety ;

(5)The operation is simple, and the main components are selected from internationally renowned manufacturers ;

(6)The original imported oxygen molecular sieve is used, which has superior performance and long service life.

Technical index/Технические показатели

Capacity:100~10000Nm3/h

Oxygen pressure:0.015~0.05MPa(adjustable )

Oxygen purity: 30~95.0%