Membrane air separation equipment

Working principle

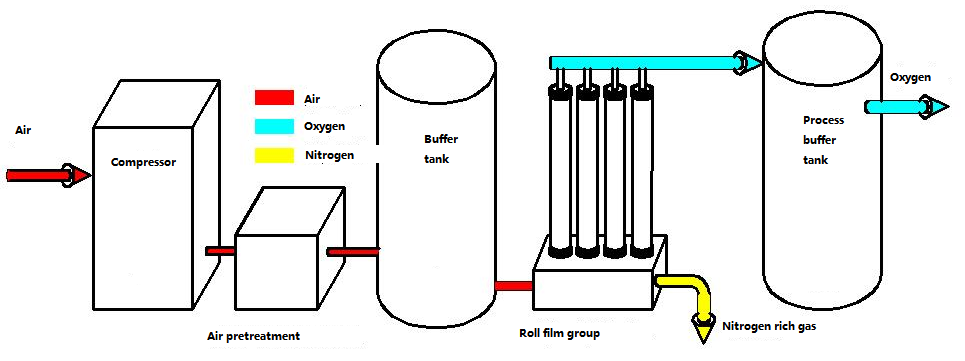

The compressed air passes through the air purification device to remove solid impurities such as oil and dust and most of the gaseous water, and enters the membrane separation system. Under the action of pressure, the adsorption, diffusion, and permeation rates of various gases in the hollow fiber membrane are different, and they are arranged in order to achieve the separation of oxygen and nitrogen. Under PLC control, it can realize continuous and stable output of finished oxygen or nitrogen.

Technical features:

▲Low operating energy consumption, economically meeting the different needs of users for oxygen;

▲large oxygen output and stable flow;

▲ Static operation, extremely low failure rate, and small maintenance workload;

▲The device occupies a small area and can be used for indoor and mobile field operations;

▲The integrated design of standard membrane modules makes it easy to expand the production of finished gas by adding membrane separation modules;

▲High degree of automation, convenient and quick to start and stop; the product gas concentration can be reached within 10 minutes;

▲No noise and pollution during the operation of the equipment, and the product gas clean and with low dew point;

▲In terms of combustion-supporting, it occupies great advantage in air separation methods and has low operating energy consumption.

Membrane separation oxygen production equipment

Technical inde

·Oxygen output: 1~ 20000Nm3/h, when the oxygen concentration is 30%, the investment, maintenance and use cost of the membrane method is only about 70% to 80% of the cryogenic and (V) PSA method, and the larger the scale, the more the membrane method is relatively economy

·Oxygen purity: 30%-45% (the purity of the oxygen in the secondary separation can reach: 90%) .

Principle diagram /

Membrane separation nitrogen production equipment

Technical index

·Nitrogen output : 1~3000Nm3/h

·Nitrogen purity: 95~99.9%

·Nitrogen pressure: 0.1~1.2MPa (adjustable)

·Nitrogen dew point: -40~-60℃