Deep-cold distillation and cryogenic air separation equipment

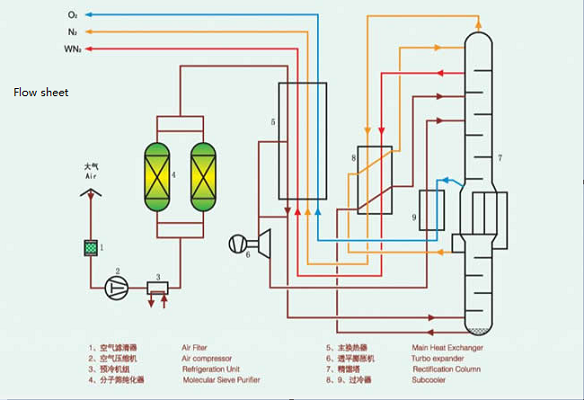

Working principle

The principle is to use air separation technology to compress the air with high density, and then use the different condensation points of the components in the air to separate the gas and liquid at a certain temperature, and then further rectify it.

Equipment supplied: capacity 800m3/h and below; capacity 1000-6000m3/h; capacity 10000m3/h and above.

Air separation equipment is generally composed of air compressor, pre-cooling device, purification device, air separation tower and so on.

According to the technological process, it can be divided into five basic systems:

1.Impurity purification system

2.Air-cooled liquefaction system

3.Air distillation system

4.Heating and purging system

5.Instrument control system

Ultra low pressure type air separation equipment

Through deep optimization of the air separation process, the operating pressure of the raw material air compressor is minimized. The ultra-low pressure air separation unit has remarkable energy-saving effect, mature patented technology, simple and reliable process.

High pressure internal compression air separation equipment

The special process and cryogenic liquid pump are used to achieve the purpose of producing high-pressure product. More advanced technology is applied to this process and it runs stably.

Full liquid air separation equipment / Оборудование разделения воздуха в жидкостной форме

According to customer needs, we make and supply cryogenic liquid production equipment such as equipment for liquid oxygen, liquid nitrogen and liquid argon.

High purity nitrogen device

According to the needs of customers, we can produce and supply equipment for production of pure nitrogen, high-purity nitrogen or ultra-pure nitrogen.

The above-mentioned process organization and equipment configuration are flexible and changeable, which can achieve the perfect combination of energy consumption and investment while taking into account operability and stability.

Application field

Iron and steel industry, non-ferrous smelting, environmental protection, petrochemical industry, coal chemical industry, etc.